Efficient thermal management is essential in modern industry and machinery. At the heart of these systems lies the coolant flow sensor, which plays a crucial role in maintaining optimal performance and preventing costly breakdowns. This article delves into the workings of coolant flow sensor, their benefits, applications, and how innovations by Proteus Industries Inc. are advancing the industry.

What Is a Coolant Flow Sensor?

A coolant flow sensor is a device designed to measure the flow rate of coolant in a thermal management system. It ensures the right amount of coolant flows through the system, maintaining temperature control and preventing overheating. This precision allows machines to operate efficiently under various conditions.

These sensors are indispensable in applications where overheating could result in equipment failure or safety hazards. Providing real-time data enables proactive maintenance and adjustments and ensures smooth operation.

The Role of Coolant in Machines

Coolant is a specially formulated liquid designed to absorb and dissipate heat from an machine efficiently. Without adequate coolant circulation, machine components can overheat, causing irreversible damage.

A coolant flow sensor ensures that coolant flows at the correct rate, allowing it to absorb heat effectively and keep temperatures within safe limits. This is critical for extending the life of components, enhancing fuel efficiency, and minimizing emissions.

Why Coolant Flow Monitoring Is Crucial

Monitoring coolant flow is essential for several reasons:

- Prevents Overheating: Ensures proper cooling to avoid machine damage.

- Detects Issues Early: Identifies blockages, leaks, or pump failures before they cause significant problems.

- Optimizes Performance: Maintains the machine at its ideal operating temperature.

A malfunctioning cooling system can lead to catastrophic machine failures, downtime, and expensive repairs. By integrating a coolant flow sensor, operators can address potential issues proactively.

Benefits of Using Coolant Flow Sensors

- Enhanced Efficiency: Sensors ensure the cooling system operates optimally, reducing energy wastage.

- Improved Longevity: Proper cooling minimizes wear and tear, extending the lifespan of machines.

- Reduced Maintenance Costs: Early detection of issues prevents costly repairs and downtime.

- Environmental Sustainability: Efficient coolant usage lowers emissions and waste.

These benefits make coolant flow sensors an invaluable addition to any thermal management system.

Real-Time Monitoring for Machine Efficiency

Modern coolant flow sensors provide real-time data on coolant flow rates. This allows operators to adjust machine parameters dynamically, ensuring peak efficiency. Real-time monitoring prevents overheating, optimizes fuel consumption, and reduces environmental impact.

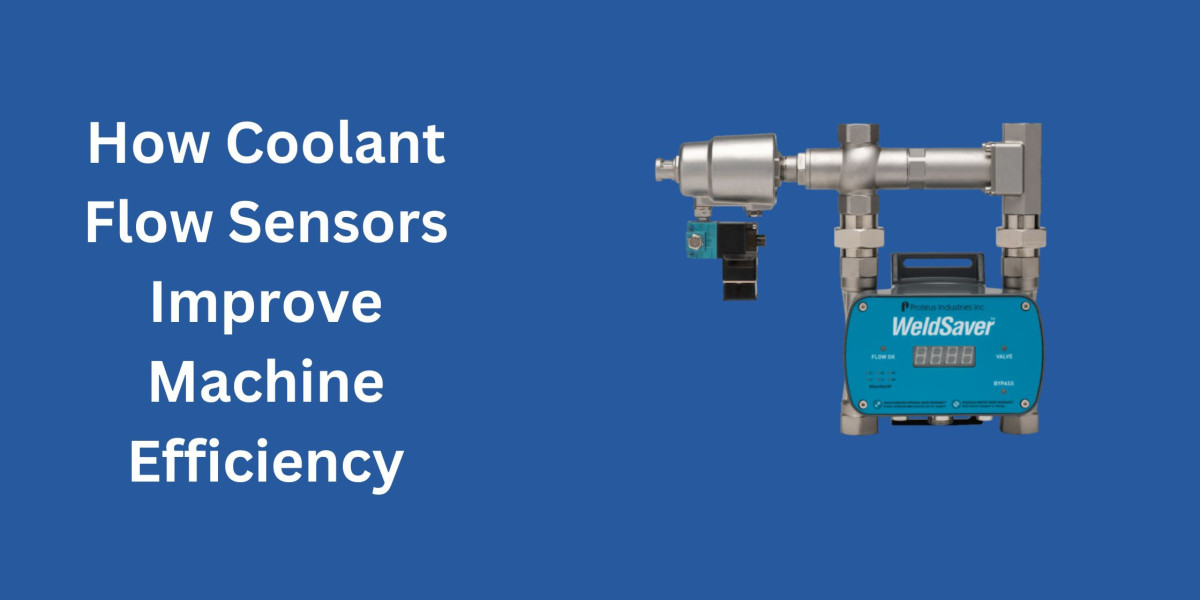

Innovative Solutions from Proteus Industries Inc.

Proteus Industries Inc. is a coolant flow sensor technology leader, offering cutting-edge products tailored to various industries. Their sensors are known for their:

- High Accuracy: Reliable readings under challenging conditions.

- Durability: Built to withstand extreme environments.

- Advanced Integration: Seamlessly connects with IoT and intelligent systems.

The companys commitment to innovation and quality has made it a trusted name in the automotive, aerospace, and manufacturing industries.

Conclusion

A coolant flow sensor is vital for improving machineefficiency, reducing maintenance costs, and promoting sustainability. Advanced solutions from Proteus Industries Inc. ensure unmatched accuracy, durability, and adaptability for diverse industrial applications. Investing in these sensors is not just about improving performanceits about future-proofing operations against rising demands for efficiency and sustainability.

FAQs About Coolant Flow Sensors

1. What is the primary function of a coolant flow sensor?

It measures the flow rate of coolant to maintain optimal thermal management.

2. How does a coolant flow sensor improve efficiency?

It prevents overheating and ensures the machine operates at its ideal temperature, reducing energy loss.

3. What makes Proteus Industries Inc. sensors unique?

They offer high precision, durability, and seamless integration with advanced systems.

4. Can coolant flow sensors be used in older machines?

Yes, but proper retrofitting or upgrades may be needed for compatibility.

5. How often should sensors be serviced?

Regular inspections every 612 months are recommended.

6. Are coolant flow sensors environmentally friendly?

Yes, they contribute to sustainability by reducing coolant wastage and energy consumption.

7. Which industries benefit most from coolant flow sensors?

The automotive, aerospace, electronics, and manufacturing sectors have the most advantages.