In the machining process of CNC machine tools, the relationship between cutting force and surface quality is a very important problem. biaxial cnc machine is widely used in modern manufacturing industry because of its high precision, high efficiency and high stability. In this paper, the relationship between the cutting force and the surface quality of the hard rail machine tool is discussed, and how to optimize the surface quality of the hard rail machine tool is discussed.

Cutting force: In the processing of CNC machine tools, cutting force is a very key parameter. The cutting force directly affects the machining efficiency and machining quality. In the process of cutting, the hard rail machine tool is mainly affected by four forces: cutting force, tangential force, radial force and wear force. The size and mode of action of these forces are completely different, but their combined effect determines the processing efficiency and processing quality of hard rail machine tools.

Second, surface quality: the surface quality of CNC machine tools refers to the flatness, smoothness and roughness of the surface of the workpiece machined by the machine tool in the process of CNC machine tool processing. The quality of the surface directly affects the quality and service life of the parts processed by the machine tool. Therefore, the surface quality of biaxial cnc machines is a very important issue in the manufacturing industry.

Third, the relationship between cutting force and surface quality: In the processing of hard rail machine tools, there is a certain relationship between cutting force and surface quality. The size and direction of the cutting force will affect the surface quality of the machined workpiece. Sometimes, the cutting force is too large to cause the deformation of the machine tool structure or the surface quality of the workpiece obvious defects, and sometimes the cutting force is too small and will lead to low processing efficiency or surface quality roughness is too high.

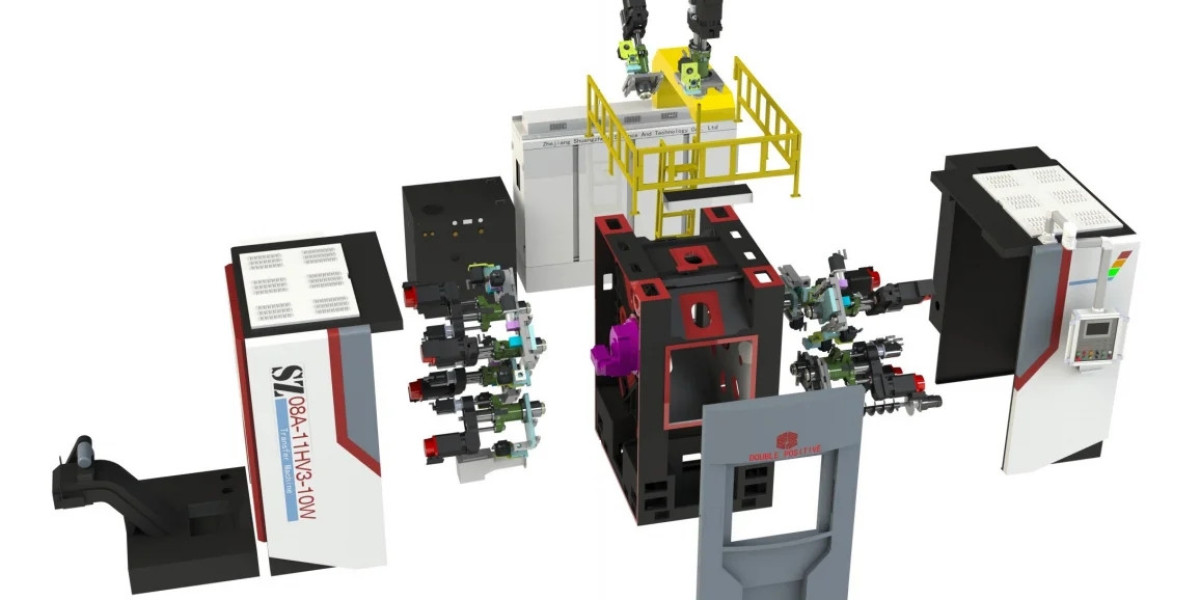

biaxial cnc machine

Therefore, during the processing of the biaxial cnc machine, it is necessary to ensure the balance between the cutting force and the surface quality through certain technical means and parameter adjustment. Specifically, hard rail machines need to optimize the relationship between cutting force and surface quality by:

1, cutting parameters adjustment: according to the characteristics of different materials and workpieces, adjust the cutting speed, feed speed and cutting depth and other parameters.

2, processing lubrication: through proper lubrication, you can reduce the size of the cutting force, but also make the surface quality of the workpiece machined by the machine tool more stable.

3, hardness and material selection: by choosing the right hardness and material, you can effectively control the cutting force, thereby improving the processing efficiency and surface quality.

In summary, cutting force and surface quality are two important parameters in the machining process of biaxial cnc machine. By adjusting the appropriate cutting parameters, processing lubrication and selecting the appropriate hardness and material, the balance between the cutting force and surface quality can be achieved, thereby improving the machining efficiency and processing quality of the machine tool.

biaxial cnc machine https://www.zjshuangzheng.com/