Poland is today one of the most important industrial centers in all of Europe, especially when it comes to manufacturing. Many machine parts manufacturers in the country are highly advanced and reliable, providing global solutions to any number of industries. From automotive and aerospace to agricultural and energy domains, Polish manufacturers are making modern products with innovation and engineering finesse to cater to domestic as well as foreign markets.

Why Poland Is a Hub for Machine Parts Manufacturing

The manufacturing authority that Poland enjoys is due to the strong strategic location it enjoys, technical and professional workforce, and the continuous investments into industrial growth. Let us see why Poland stands above the rest in this field:

1. Strategic Location

Geographically central in Europe, Poland offers tremendous accessibility to markets from the west to the east. Thus, machine parts manufactured here are easily traded and exported internationally to neighboring countries like Germany, France, UK, and Italy.

2. Skilled Workforce

Every year, thousands of engineers and technicians are produced by Polish higher and technical education with strong engineering and technical foundations. This skilled workforce, in turn, guarantees the production of machine parts of quality, precision, and reliability.

3. Advanced Manufacturing Infrastructure

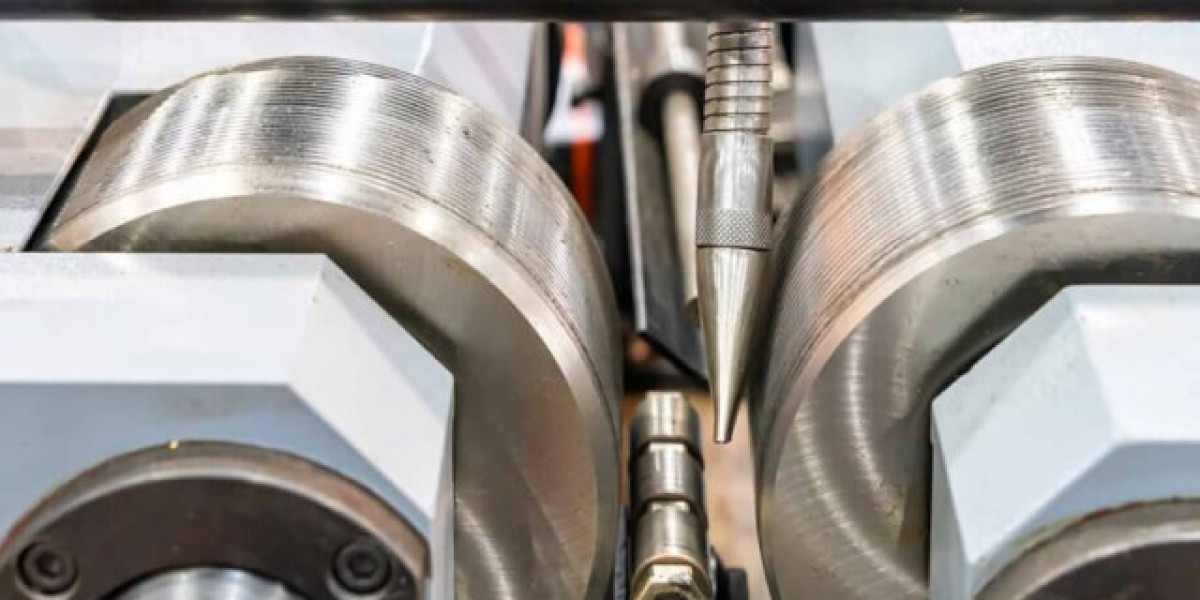

Modern-day manufacturing infrastructure in Poland comprises advanced CNC machines, CAD/CAM systems, 3-D-printing technology, and robotic automation. Utilizing these technologies largely enhances precision and further increases the rate of production for manufacturers.

Government Support and EU Funding

Industrial Polish manufacturers have enjoyed the support of government campaigns and European Union funding designed to encourage innovation, research, and development in industrial sectors. This fast-tracked the modernization of production plants, which consequently gained greater competitive advantage in the international market.

Industries Served by Machine Part Manufacturers in Poland

The production of machine parts for metallurgy and heavy machinery in Poland is catered to different industries, each with its particular set of specifications and tolerances. The important ones are:

- The Automotive Industry

Manufacturing automotive components is one of the most represented industries in Poland. Manufacturers make gears, shafts, engine parts, brake components, and suspension parts for automotive brands in the world market.

- Agriculture

It largely includes the manufacturing of heavy parts for tractors, harvesters, and farming equipment, among which are gearboxes, drive systems, hydraulic parts, and engine components.

- Aerospace

The aerospace industry demands ultra-high precision, and the Polish companies have the know-how to deliver turbine components, casings, brackets, and fasteners for both aircraft and helicopters.

- Energy and Power

From wind turbines to hydraulic systems, machine parts, such as couplings, seals, rotors, and pumps, are developed in terms of the best material quality and durability.

- Construction Equipment

Parts for excavators, bulldozers, and cranes, like sprockets, bushings, pins, and arms, are made to withstand the harshest working conditions.

Types of Machine Parts Manufactured in Poland

Machine parts manufactured in Poland cover a very large variety in terms of materials and processes. The most popular are:

Shafts and Axles

Used in automotive, industrial, and mechanical systems.

Gears and Gearboxes

Parts involved with motion and power transmission.

Bearings and Bushings

Manufactured with high tolerance for such precision to ensure smooth operation.

Hydraulic and Pneumatic Parts

Cylinders, valves, and manifolds used in fluid power systems.

CNC Turned and Milled Components

Custom components for machinery of different complexities in geometries.

Casting and Forging Parts

Parts processed under high pressure and temperature for extra strength and durability.

Welded and Fabricated Assemblies

Structural machine parts constructed via precision welding and fabrication.

Technologies used by the machine parts manufacturers in Poland

Modern Polish industries employ the latest production technologies, thereby granting quality, repeatability, and efficiency. They include:

1. CNC Machining

Computer Numerical Control machining is used to manufacture parts with extremely fine tolerances. 3-, 4-, and 5-axis CNC machines are frequently used.

2. CAD/CAM Design

Advance design software is used by manufacturers to allow for prototyping and simulation so that the speed of development and customization of new products is increased.

3. 3D Printing and Rapid Prototyping

Some manufacturers use the technologies of additive manufacturing to produce prototypes and manufacture complex small-batch parts.

4. Heat Treatment

Processes like carburizing, nitriding, and induction hardening generally improve wear resistance and mechanical strength.

5. Surface Treatments

Anodizing, powder coating, galvanizing, etc., are given to those finishes that protect the parts from corrosion or improve the appearance.

Quality Control and Certification Process

machine parts manufacturers in Poland have strict quality management systems in place to ensure product reliability and safety. Most eminent suppliers are certificated for:

ISO 9001 (Quality Management)

ISO 14001 (Environmental Management)

ISO/TS 16949 (Automotive)

AS 9100 (Aerospace)

They also conduct regular inspections such as:

Coordinate Measuring Machine (CMM) Checks

Material Testing (Hardness, Tensile, Impact)

Ultrasonic and Magnetic Particle Inspection (NDT)

Dimensional and Visual Inspections

These practices guarantee that each part meets its client's specification and performance requirements.

Benefits when Working with Polish Machine Parts Manufacturer

Hiring a trusted manufacturer from Poland will localize several benefits:

✔ Competitive Pricing

Compared to Western Europe and the U.S, Poland offers cost-efficient manufacturing solutions yet ensuring quality.

✔ Custom Manufacturing

Several companies tend to offer custom manufacturing upon your designs or reverse engineering from a sample.

✔ Fast Turnaround

With state-of-the-art infrastructure and establishment of skilled teams, Polish enterprises proclaim timely deliveries with quick lead times.

✔ Export-Ready Services

Numerous manufacturers experience exporting business and can help you with logistics, documentation, and packaging.

✔ Long-Term Relationships

Polish manufacturers are famous for their spirit to create a long-term business relationship that is based on trust and transparency.

How to Choose the Right Machine Parts Manufacturer in Poland

Following are some useful tips that can help you select the right manufacturing partner:

✅ Check Experience and Industry Focus

Find a manufacturer with real knowledge in your specific industry or product category.

✅ Inquire About Facilities and Technology

Find out what they use as machinery, software, and processes.

✅ Confirm Certification and Quality Standards

Make sure that the company is up to international standards for quality, safety, and environment.

✅ Request Samples and Case Studies

Request samples or case studies of products that represent their skills.

✅ Talk about Options for Customization

Evaluate whether or not they are able to customize parts according to your specifications and your design needs.

✅ Assess Communication and Assistance

Clear communication, transparency, and responsiveness are some of the spheres that will make your collaboration a really pleasant experience.

Prime Machine Parts Producers in Poland

While there are many efficient machine parts manufacturers in Poland, here are some very well known and trusted lists of machine parts industry in Poland:

Ponar Wadowice S.A. - Specialists in hydraulic systems and machine components.

Fabryka Obrabiarek RAFAMET S.A. - Supplemented with precision machining for railway components.

Metaltech-Piasecki - Custom metal parts, CNC machining, and sheet metal fabrication.

Famet S.A. - One of the oldest and most versatile producers of industrial parts.

Zamet Industry S.A. - Heavy-duty components and complex assemblies.

Final Thoughts

Poland has deposited its reputation worldwide as a trustworthy and innovative machine parts manufacturer. The luxurious single or triple combination of cheap solutions, high engineering standards, and state-of-the-art technology makes Polish companies ideal for sourcing precision machine components.

Already optimizing your supply chain or launching a new mechanical product? Collaborating with a Polish machine parts manufacturer may grant you a competitive advantage. To reap the full benefits of such cooperation, make sure to select a company that will complement your quality expectations, time scales, and technical pressings.