Polypropylene is one of the most widely used thermoplastic materials, known for its versatility, cost-effectiveness, and unique properties. It is used in a wide range of industries, from packaging and automotive to textiles and healthcare. With its remarkable characteristics and adaptability, polypropylene has become a material of choice in manufacturing and product design.

In this article, we will explore the essential properties of polypropylene material, its common applications, and the advantages it offers in various industries. We will also discuss how it compares to other plastics, why it is favored in many manufacturing processes, and the environmental considerations surrounding its use.

What is Polypropylene?

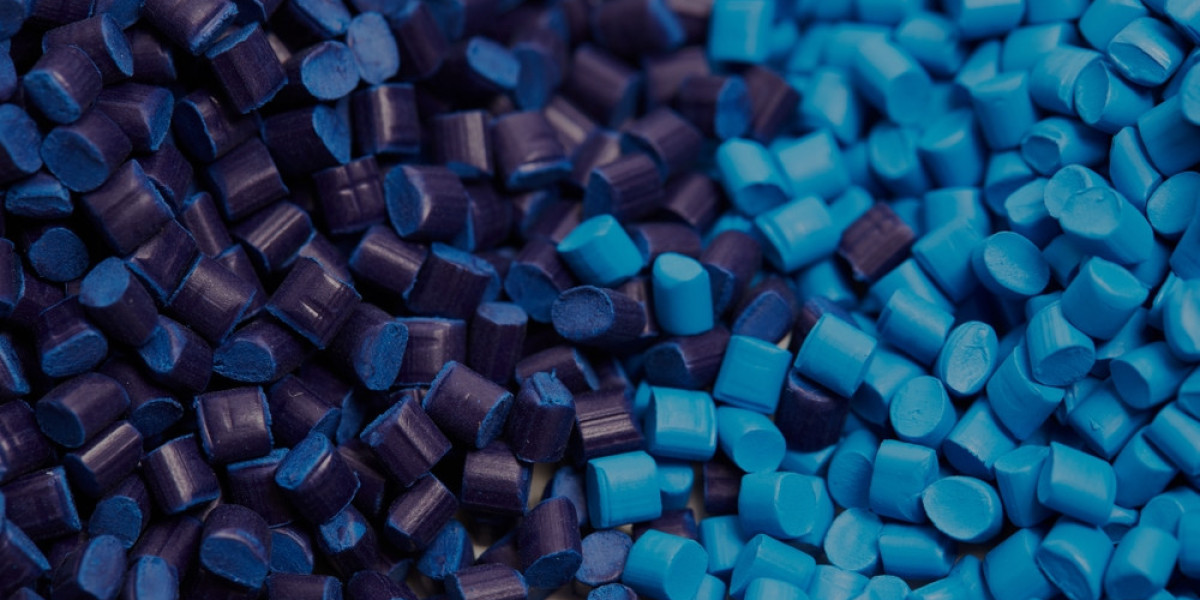

Polypropylene (PP) is a type of polymer made from the polymerization of propylene monomers. It belongs to the family of polyolefin plastics, which also includes polyethylene (PE) and polybutene (PB). Polypropylene is a crystalline thermoplastic that can be processed using a variety of methods, including injection molding, extrusion, blow molding, and thermoforming. It is a lightweight, durable, and chemically resistant material that can be produced in different grades for specific applications.

Polypropylene is considered one of the most versatile plastics, with its molecular structure giving it excellent chemical resistance, high melting point, and rigidity. These qualities, combined with its affordability, make it a go-to material in numerous industries.

Properties of Polypropylene

Polypropylene stands out in the world of plastics due to its distinctive set of properties, which contribute to its widespread use. Below are some of the key properties that make polypropylene a desirable material for various applications:

1. Durability and Strength

Polypropylene is known for its impressive mechanical strength and durability, even under harsh environmental conditions. It has high resistance to wear, impact, and fatigue, making it ideal for products that require long-lasting performance. Polypropylene's ability to retain its strength at lower temperatures also contributes to its overall toughness.

2. Chemical Resistance

Polypropylene offers excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This makes it particularly suitable for use in environments where exposure to corrosive substances is common. It is often used in packaging materials for chemicals, as well as for storage containers that hold corrosive substances.

3. Low Density

Polypropylene has a relatively low density compared to many other plastics, which means it is lightweight and easy to handle. This property makes it an ideal material for products where weight is a consideration, such as in the automotive and packaging industries.

4. Heat Resistance

Polypropylene has a high melting point compared to other plastics, typically around 160-170°C (320-338°F). This heat resistance allows it to be used in applications that require exposure to higher temperatures, such as in food containers or industrial parts that must withstand heat.

5. Electrical Insulation Properties

Polypropylene has excellent electrical insulating properties, which make it a popular choice for components in electrical and electronic devices. It is often used for insulation in wiring and capacitors, as well as in other components that require non-conductive materials.

6. Versatility in Processing

Polypropylene can be easily molded into a variety of shapes and forms using different processing techniques, including injection molding, blow molding, and extrusion. Its versatility in processing allows manufacturers to create an extensive range of products with varying characteristics.

7. Non-Toxic and Safe for Food Contact

Polypropylene is considered non-toxic and safe for food contact, which makes it a popular material for packaging, especially for food and beverages. It is resistant to staining and odors, which helps maintain the integrity and safety of food products over time.

8. Moisture Resistance

Polypropylene is hydrophobic, meaning it repels water and does not absorb moisture. This property makes it ideal for use in applications where exposure to water or humidity is common, such as in packaging for liquid products or in outdoor products exposed to rain and humidity.

Applications of Polypropylene Material

Polypropylene's unique combination of properties allows it to be used in a wide variety of applications across many industries. Some of the most common uses of polypropylene include:

1. Packaging

Polypropylene is commonly used in packaging applications due to its lightweight, durable, and chemical-resistant properties. It is widely used in making packaging materials for food products, beverages, and non-food items. Polypropylene is used to make plastic containers, bottles, caps, and film wraps. It is also used in the production of food storage containers, such as Tupperware, as well as in bags and pouches for consumer goods.

2. Automotive Industry

In the automotive industry, polypropylene is used to manufacture a range of components, including bumpers, interior panels, door trims, and dashboards. Its low density and high resistance to impact make it a preferred material for automotive parts that need to be both lightweight and durable. Additionally, polypropylene's resistance to heat and chemicals makes it suitable for under-the-hood components, such as battery cases and fuel tanks.

3. Textiles

Polypropylene is a key material in the textile industry, especially for nonwoven fabrics. It is used to produce products like disposable diapers, medical gowns, filters, and wipes. Polypropylene fibers are also used in carpets, rugs, and upholstery because of their durability, stain resistance, and low moisture absorption.

4. Medical Devices and Healthcare Products

Polypropylene's non-toxic and chemically resistant nature makes it ideal for a wide range of medical applications. It is used in the production of syringes, surgical instruments, medical containers, and implants. Additionally, polypropylene's ability to resist bacterial growth makes it suitable for products such as bandages, masks, and surgical drapes.

5. Construction

In the construction industry, polypropylene is often used in the production of pipes and fittings. Due to its chemical resistance and durability, polypropylene pipes are ideal for use in hot water systems and chemical transport applications. It is also used in geotextiles, insulation materials, and reinforcing fibers for concrete.

6. Consumer Goods

Polypropylene is commonly used in the manufacturing of household products, including furniture, storage containers, toys, and cleaning tools. Its durability, ease of processing, and cost-effectiveness make it an ideal material for everyday products that require strength and long-lasting use.

7. Electrical and Electronic Components

Due to its excellent electrical insulation properties, polypropylene is widely used in the electronics industry for components such as capacitors, insulation for wires and cables, and circuit boards. It is particularly effective in applications that require stability under heat and electrical stress.

Advantages of Polypropylene

Polypropylene offers several key benefits, which contribute to its popularity in manufacturing and product design:

1. Cost-Effective

Polypropylene is relatively inexpensive to produce compared to other plastics. Its low cost and abundant supply make it an attractive option for mass production in various industries.

2. Recyclable

Polypropylene is a recyclable material, which means that products made from PP can be recycled and reused to make new items. This helps reduce the environmental impact of plastic waste and supports sustainable manufacturing practices.

3. Lightweight

Polypropylene is lighter than many other plastics, which makes it ideal for use in applications where weight is a concern. In industries like automotive manufacturing, the use of polypropylene helps reduce the overall weight of products, which can lead to improved fuel efficiency and performance.

4. Environmental Resistance

Polypropylene's resistance to moisture, chemicals, and heat makes it a highly durable material, capable of withstanding the rigors of various environmental conditions. This makes it perfect for use in outdoor products, chemical containers, and automotive components exposed to extreme conditions.

5. Versatility in Design

Polypropylene's ability to be processed into a wide range of shapes and forms makes it highly adaptable for diverse applications. Whether it's molded into complex shapes, extruded into sheets, or spun into fibers, polypropylene offers design flexibility that few materials can match.

Environmental Considerations

While polypropylene is a recyclable material, the environmental impact of its production and disposal must be considered. As with many plastics, polypropylene can contribute to plastic waste if not properly recycled. Efforts are being made in various industries to improve polypropylene's recyclability and encourage more sustainable production practices. However, the overall environmental impact of polypropylene is still lower compared to some other plastics, especially when it is recycled or reused in manufacturing processes.

Conclusion

Polypropylene is a versatile and highly durable material that offers a wide range of benefits across many industries. Its strength, chemical resistance, heat tolerance, and lightweight properties make it an ideal choice for applications in packaging, automotive, healthcare, textiles, and more. With continued innovations in recycling and processing technologies, polypropylene is likely to remain a go-to material for manufacturing products that require durability, cost-effectiveness, and versatility.