Introduction

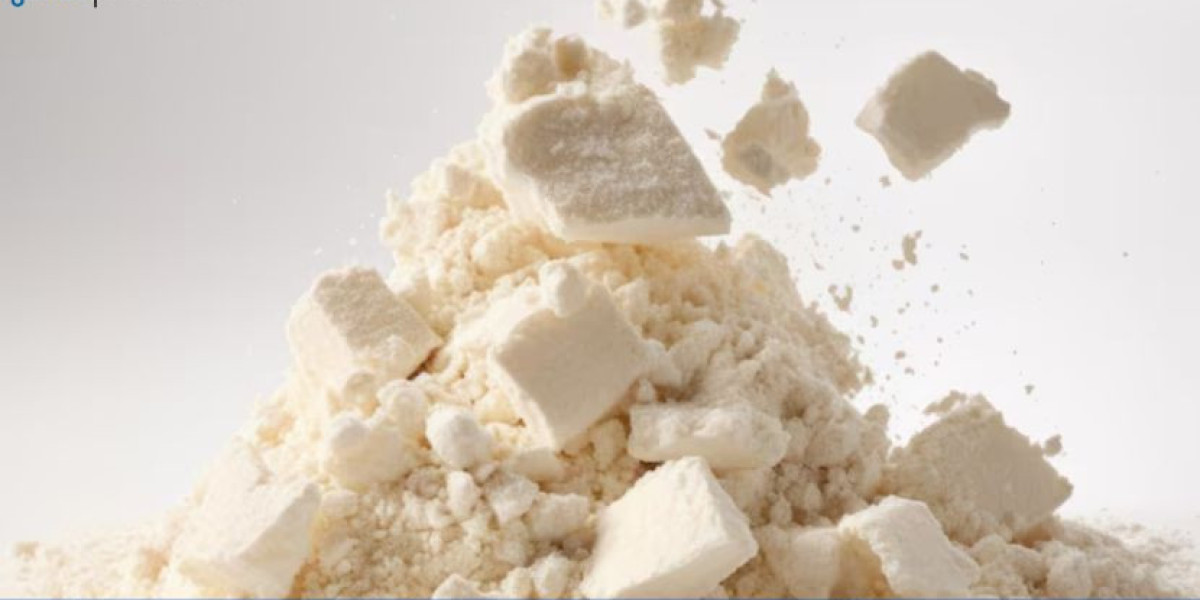

A Tofu Powder Manufacturing Plant Project Report offers a comprehensive guide for establishing a plant dedicated to the production of tofu powder, a versatile and increasingly popular food ingredient. Tofu powder is derived from soybeans and serves as an easy-to-use alternative to traditional tofu, often used in vegan, vegetarian, and health-conscious diets. Its compact, shelf-stable nature makes it a convenient option for both domestic and commercial use. This report outlines the key aspects of setting up a tofu powder manufacturing plant, including raw material sourcing, machinery, production processes, market dynamics, financial considerations, and regulatory requirements.

Market Overview of Tofu Powder

The tofu powder market has gained significant traction in recent years due to the growing demand for plant-based, gluten-free, and dairy-free alternatives to traditional food products. Several key trends are driving the demand for tofu powder, including:

Increasing Vegan and Plant-Based Diets: With a rising number of individuals adopting plant-based and vegan diets, the demand for tofu and its derivatives, including tofu powder, has skyrocketed. Tofu powder offers a versatile alternative to traditional tofu blocks, which are perishable and bulky.

Convenience and Long Shelf Life: Tofu powder has a long shelf life and is much easier to store and transport compared to fresh tofu. This makes it an appealing option for both consumers and food manufacturers looking for convenience and ease of use.

Health and Wellness Trends: As consumers become more health-conscious, there is a growing preference for plant-based proteins like soy. Tofu powder, being rich in protein and low in fat, aligns well with the demand for healthy food options.

International Market Demand: Tofu powder is not only popular in traditional markets like Asia but is also gaining acceptance in Western countries as a meat substitute, especially among those seeking alternatives to animal protein.

As tofu powder continues to gain popularity in food industries such as ready-to-eat meals, snacks, and meat substitutes, the market is expected to grow steadily.

Get a Free Sample Report with Table of Contents@

Raw Materials for Tofu Powder Manufacturing

The primary raw material for producing tofu powder is soybeans, which are processed to extract soy protein and other components used in the powder production. Some other materials and ingredients that may be required include:

Soybeans: The main raw material, soybeans are rich in protein, which is essential for making tofu powder. High-quality, non-GMO soybeans are preferred to ensure the best product quality.

Coagulants: Common coagulants used in tofu production include magnesium chloride (nigari) or calcium sulfate (gypsum). These are added during the tofu-making process to help curdle the soy milk and form tofu.

Additives: Depending on the desired characteristics of the tofu powder, various additives may be used, such as flavour enhancers, preservatives, or thickeners.

Packaging Materials: Tofu powder must be packaged in a way that preserves its shelf life. Packaging materials include air-tight bags or containers, often made of plastic, aluminium foil, or paper with moisture-barrier properties.

Flavourings and Seasonings: Some tofu powders are flavoured to cater to different culinary needs. Ingredients such as herbs, spices, or nutritional yeast may be added to enhance the taste of the powder.

Production Process for Tofu Powder

The production process for tofu powder involves several steps, from soybean processing to the final packaging. Below is an overview of the key stages:

1. Soybean Cleaning and Preparation

The first step in the tofu powder manufacturing process is the cleaning and preparation of soybeans. Soybeans are thoroughly cleaned to remove impurities such as dust, stones, and broken beans. The soybeans are then soaked in water to soften them before the extraction of soy milk.

2. Soy Milk Extraction

Once the soybeans are soaked, they are ground into a fine paste, which is then mixed with water to form soy milk. The soy milk is filtered to remove the remaining solid particles, leaving behind a smooth liquid.

3. Tofu Production (Curdling)

To form tofu, a coagulant (such as calcium sulfate or magnesium chloride) is added to the soy milk. The milk curdles to form solid tofu curds, which are separated from the whey.

4. Dehydration of Tofu

The tofu curds are then dehydrated to remove excess moisture. This is usually done by either pressing the tofu curds or using a drying process such as freeze-drying or spray-drying. The goal is to achieve a low moisture content, which is essential for turning the tofu into a powder form.

5. Grinding and Powdering

The dehydrated tofu is then ground into a fine powder. This step requires the use of grinding mills or pulverisers to ensure that the tofu powder is uniform in texture and consistency. The powdered tofu is carefully sifted to remove any larger particles.

6. Packaging

Once the tofu powder has been produced, it is packaged in air-tight containers to preserve freshness. Packaging materials such as vacuum-sealed bags, jars, or resealable pouches are commonly used to ensure the product remains dry and stable during transport and storage.

Machinery and Equipment for Tofu Powder Manufacturing

The production of tofu powder requires a variety of machinery and equipment to ensure high-quality, efficient manufacturing. Some key equipment required for this process includes:

Soybean Cleaning Machine: Used to clean the soybeans and remove any foreign particles, dust, or damaged beans.

Soybean Grinder/Blender: This machine is used to grind the soaked soybeans into a paste before the soy milk is extracted.

Soy Milk Extractor: A filtration system to extract soy milk from the soybean paste, separating the liquid from the solid components (soy pulp).

Coagulation Tank: Used to add coagulants to the soy milk, causing it to curdle and form tofu.

Pressing Machine: This equipment is used to press the tofu curds and remove excess water, ensuring proper dehydration of the tofu.

Dehydration Equipment (Spray Dryer or Freeze Dryer): These machines remove moisture from the tofu curds, ensuring they are completely dried to create tofu powder.

Grinding Mill: A grinder or pulveriser is used to grind the dried tofu into a fine powder. The grinding process ensures the consistency of the final product.

Packaging Machine: Once the tofu powder is ready, packaging machines seal the product in airtight bags or containers to maintain its freshness and shelf life.

Plant Location and Layout

The location and layout of the tofu powder manufacturing plant are crucial for operational efficiency, cost control, and accessibility. Key factors to consider include:

Proximity to Raw Material Suppliers: The plant should ideally be located near soybean farms or suppliers to reduce transportation costs for raw materials.

Logistics and Distribution: The plant should be easily accessible to major transportation hubs for the efficient distribution of finished products to national and international markets.

Environmental Considerations: The facility should be designed to meet environmental regulations regarding waste management, water usage, and energy consumption.

Space for Expansion: As the demand for tofu powder grows, having additional space for scaling production or adding more equipment can be beneficial.

Employee Welfare: The plant should be designed with employee safety in mind, including proper ventilation, sanitation, and health facilities.

Regulatory Compliance and Safety Standards

Compliance with food safety regulations is critical in tofu powder manufacturing. Key regulations include:

Food Safety Standards: The plant must adhere to local and international food safety standards, including those set by the FDA (Food and Drug Administration) or other relevant authorities. This includes ensuring that the product is free from contaminants and harmful substances.

Quality Certifications: ISO 9001 or other quality management certifications may be required to ensure that the manufacturing process meets global standards.

Packaging Regulations: Packaging materials must meet health and safety regulations, ensuring that the tofu powder is packaged in safe, non-toxic containers.

Environmental Regulations: Compliance with waste management and pollution control standards is necessary, especially when handling large quantities of soybeans and by-products.

Financial Considerations

The financial aspects of establishing a tofu powder manufacturing plant are crucial to the success of the business. Key financial factors include:

Initial Capital Investment: This includes the cost of land, machinery, construction, raw materials, and labour. The capital investment required will vary depending on the scale of production.

Operational Costs: Regular expenses include raw materials, energy costs, maintenance of machinery, labour wages, and packaging costs.

Revenue Generation: Tofu powder can be sold through multiple channels, including direct sales to consumers, wholesale distribution to food manufacturers, or export to international markets.

Profit Margins: The tofu powder market generally offers good profit margins, particularly for high-quality, organic, or specialty products. However, pricing must be competitive to attract customers.

FAQs

What is tofu powder made of?

Tofu powder is made from soybeans, which are processed into soy milk, coagulated to form tofu, and then dehydrated and ground into powder.What are the benefits of tofu powder?

Tofu powder is a high-protein, plant-based food product that is easy to store, transport, and use in various recipes.How long does it take to manufacture tofu powder?

The entire process, from soybean cleaning to the packaging of tofu powder, can take several days depending on the production scale.Is tofu powder vegan?

Yes, tofu powder is a vegan-friendly product, as it is made from soybeans, a plant-based source of protein.Can tofu powder be used in cooking?

Yes, tofu powder can be rehydrated and used in various dishes like soups, smoothies, sauces, and vegan desserts.

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au