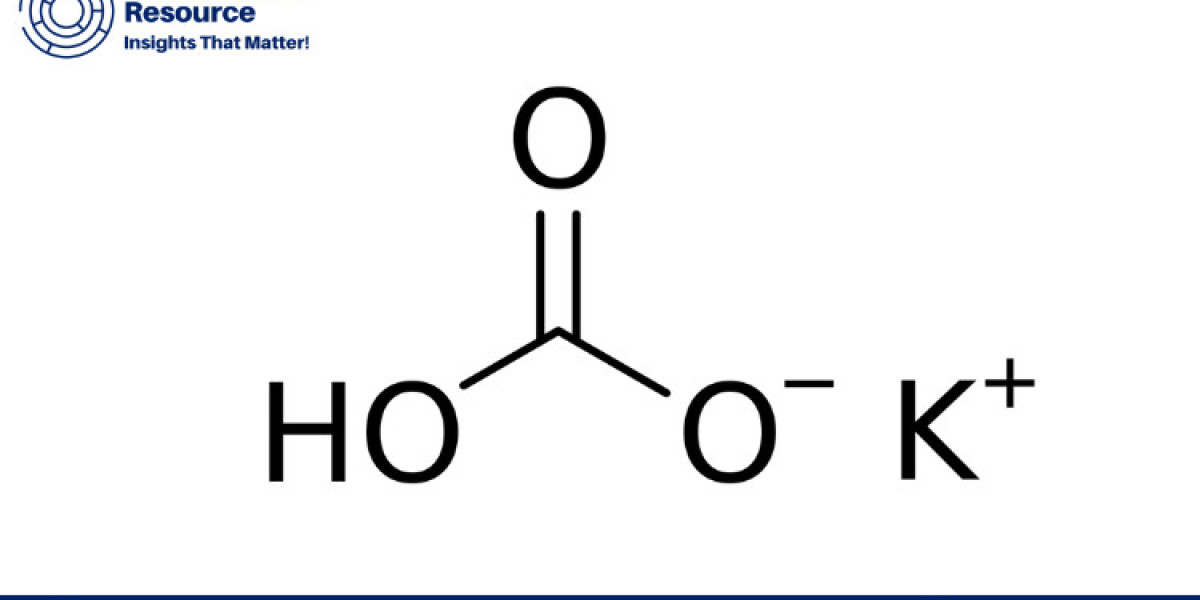

Potassium bicarbonate (KHCO₃) is a versatile inorganic compound with a wide range of applications across various industries, including agriculture, food processing, pharmaceuticals, and fire safety. Its multifunctional properties, such as acting as a buffering agent, leavening agent, and fire suppressant, make it a valuable commodity in the global market. As industries increasingly prioritize sustainable and eco-friendly solutions, the demand for potassium bicarbonate has seen a notable rise. Understanding the production cost of potassium bicarbonate is crucial for stakeholders aiming to establish manufacturing plants or optimize existing operations. This article delves into the comprehensive aspects of potassium bicarbonate production costs, encompassing cost models, pre-feasibility studies, industrial trends, labor charges, utilities, logistics, and supply chain considerations.

Cost Model and Pre-Feasibility Analysis

Establishing a potassium bicarbonate manufacturing plant requires a meticulous assessment of various financial and operational factors. A detailed cost model serves as a foundational tool, providing insights into capital investments, operating expenses, and potential revenue streams. Key components of the cost model include:

Capital Investments: This encompasses expenditures on land acquisition, site development, construction, and procurement of machinery and equipment. The choice of technology and scale of production significantly influence the initial capital outlay.

Operating Expenses: Recurring costs such as raw material procurement, labor wages, utility consumption (electricity, water, steam), maintenance, and administrative expenses fall under this category. Efficient resource management can lead to substantial cost savings in the long run.

Revenue Projections: Estimating the income generated from the sale of potassium bicarbonate and its by-products involves analyzing market demand, pricing strategies, and competitive positioning.

Conducting a pre-feasibility study is imperative to evaluate the viability of the project. This study examines market trends, supply chain logistics, regulatory requirements, and potential risks, enabling investors to make informed decisions. "Potassium Bicarbonate Manufacturing Plant Project Report 2025" offers an extensive guide on setting up a manufacturing unit, covering aspects like unit operations, raw material needs, utility supply, infrastructure, machinery models, labor requirements, transportation timelines, and packaging costs.

Request For Sample: https://www.procurementresource.com/production-cost-report-store/potassium-bicarbonate/request-sample

Industrial Trends

The potassium bicarbonate industry is influenced by several trends that shape its production and application:

Sustainable Agriculture: With the global shift towards eco-friendly farming practices, potassium bicarbonate is gaining popularity as a fertilizer, especially for chloride-sensitive crops. Its role in organic farming underscores its importance in sustainable agriculture.

Food Industry Applications: As a leavening agent, potassium bicarbonate offers a sodium-free alternative to traditional baking soda, aligning with the growing consumer demand for health-conscious food products.

Pharmaceutical Uses: In the medical field, potassium bicarbonate is utilized to manage potassium deficiencies and balance pH levels, highlighting its therapeutic significance.

Fire Safety Measures: Its effectiveness as a fire suppressant, coupled with its low environmental impact, makes potassium bicarbonate a preferred choice in fire extinguishing systems.

These trends indicate a robust growth trajectory for the potassium bicarbonate market, driven by its diverse applications and environmental benefits.

Labor Charges and Utilities

Operational efficiency in potassium bicarbonate production is heavily dependent on labor and utility management:

Labor Charges: The cost of skilled and unskilled labor varies based on geographic location, labor laws, and industry standards. Investing in training programs can enhance workforce productivity, leading to cost optimization.

Utilities: The production process consumes significant amounts of electricity, water, and steam. Implementing energy-efficient technologies and sustainable practices can reduce utility expenses. Regular audits and maintenance of equipment further contribute to cost savings.

Logistics and Supply Chain Considerations

Efficient logistics and a resilient supply chain are pivotal for the seamless operation of a potassium bicarbonate manufacturing plant:

Raw Material Sourcing: Securing a reliable supply of high-quality raw materials, primarily potassium carbonate and carbon dioxide, is essential. Fluctuations in raw material prices can impact production costs, necessitating strategic sourcing and long-term contracts.

Transportation: The distribution of the final product to various markets requires a well-planned transportation network. Factors such as proximity to target markets, transportation infrastructure, and associated costs play a crucial role in logistics planning.

Supply Chain Management: Adopting integrated supply chain management practices ensures timely procurement of raw materials and delivery of finished products. Leveraging technology for inventory management and demand forecasting can enhance supply chain efficiency.

Request a Free Sample

For a more comprehensive understanding and detailed insights into the potassium bicarbonate production process, cost analysis, and market trends, interested stakeholders can request a free sample report from Procurement Resource. This report offers an in-depth cost analysis of the production process, covering aspects such as material flow, capital investment, operating costs, and financial expenses. Accessing this sample can provide valuable information to guide investment decisions and operational strategies.

Request a Free Sample Report: https://www.procurementresource.com/production-cost-report-store/potassium-bicarbonate/request-sample

Understanding the multifaceted components of potassium bicarbonate production costs is essential for stakeholders aiming to venture into this industry. A thorough analysis encompassing cost modeling, market trends, labor and utility management, and supply chain logistics provides a solid foundation for establishing a successful manufacturing operation. As the demand for potassium bicarbonate continues to grow across various sectors, informed decision-making and strategic planning will be key drivers of profitability and sustainability in this dynamic market.

Contact Us:

Company Name: Procurement Resource

Contact Person: Endru Smith

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA